Overview

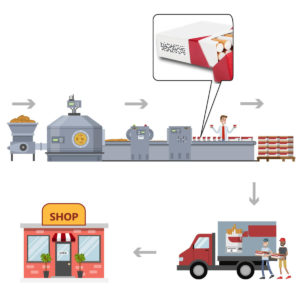

With the growing need to ensure supply of genuine tobacco products, a sizable number of industries have started to adopt product tracking techniques across the supply chain. Track n Trace Systems have been installed by many tobacco companies as one of the tools for Brand Protection and to prevent counterfeit products.

With the growing need to ensure supply of genuine tobacco products, a sizable number of industries have started to adopt product tracking techniques across the supply chain. Track n Trace Systems have been installed by many tobacco companies as one of the tools for Brand Protection and to prevent counterfeit products.

Worldwide compliance requirements for Tobacco track and trace products vary greatly by country- Russia, UAE, Europe, etc. Propix meets the stringent requirements of every country in a single system and also provides continuous updates for changes/ additions/omissions in the requirements of these compliances.

Propix is one of the only companies in the world that provides a true end-to-end solution that is Indigenously developed in-house. Our“Agni” is specially designed to facilitate the serialization process of cigarettes in the easiest and the most reliable way without affecting the speed and productivity of the manufacturing line. Establishing a parent child relationship for aggregation is very simple and intuitive, saving valuable time!

Agni fits perfectly on the existing cigarette manufacturing line, without compromising a single security and reliability feature that is essential for operation. We can easily handle high speeds of up to 600 packets per minute, and have solutions for all variants of cigarette sizes and manufacturing lines whether they are Manual lines, semi-automatic lines, fully automatic lines, high speed automatic lines etc.

Solutions for Tobacco Industry

Agni

Online Cigarettes bundle aggregation machine

Packi Track n Trace

Web-Based Plant Server Application software